Air pollution, a pressing global concern, necessitates advanced technological solutions to accurately measure and manage air quality effectively.

At the heart of these solutions lies the Printed Circuit Board (PCB), the backbone of any air monitoring terminal.

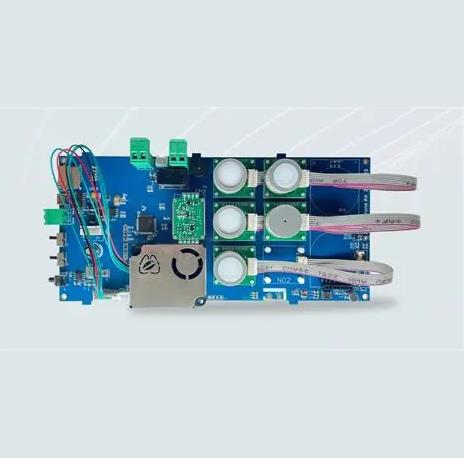

Hycxpcba specializes in providing cutting-edge PCB solutions tailored for urban air monitoring terminals, offering rapid prototyping and

one-stop services from design to manufacturing.

This article delves into the critical role of PCB solutions in enabling effective urban air monitoring, highlighting the design considerations, materials,

manufacturing processes, and the expertise that Hycxpcba brings to the table.

Introduction: The Vital Role of PCBs in Air Quality Monitoring

Urban air quality monitoring is a critical public health and environmental imperative, driving the demand for advanced and reliable sensing technologies.

At the heart of these sophisticated monitoring terminals are Printed Circuit Boards (PCBs), serving as the foundational backbone for sensor integration, data processing, and communication.

The efficacy and accuracy of urban air monitoring systems are directly proportional to the quality and specialized design of their underlying PCBs, making their role indispensable in capturing precise environmental data.

| Air Pollutant | Health Impact | Monitoring Necessity |

|---|---|---|

| Particulate Matter (PM2.5/PM10) | Respiratory and cardiovascular diseases | Real-time tracking for public health alerts |

| Nitrogen Dioxide (NO2) | Respiratory issues, acid rain | Assessing traffic emissions and industrial pollution |

| Ozone (O3) | Lung damage, agricultural impact | Ground-level ozone vs. stratospheric ozone differentiation |

| Sulfur Dioxide (SO2) | Respiratory problems, acid rain | Monitoring industrial sources and fossil fuel combustion |

| Carbon Monoxide (CO) | Reduced oxygen delivery to organs | Detecting incomplete combustion, vehicular emissions |

The escalating urbanization and industrial growth globally necessitate continuous, accurate air quality assessment. This demand fuels innovations in air monitoring terminal technology,

inherently raising the bar for PCB design and manufacturing. Specialized PCBs are not merely platforms for components;

they are finely engineered systems that must ensure signal integrity from a myriad of sensitive sensors, manage power efficiently for remote deployments,

and withstand harsh environmental conditions. Without robust and intelligently designed PCBs, the promise of smart cities and proactive environmental management remains largely unfulfilled,

underscoring their vital role in protecting public health and fostering sustainable urban development.

Understanding the Design Considerations for Air Monitoring Terminal PCBs

Designing Printed Circuit Boards (PCBs) for urban air monitoring terminals presents a unique set of engineering challenges that are critical to the accuracy, reliability

, and longevity of these vital environmental sensors. Unlike general-purpose electronics, air quality monitoring PCBs must contend with precise sensor integration,

maintain impeccable signal integrity in noisy environments, manage power efficiently for continuous operation, and withstand harsh outdoor conditions.

A deep understanding of these intertwined factors is paramount to developing a robust and high-performing monitoring system, ultimately ensuring dependable data for actionable environmental insights.

- How does sensor integration impact Urban Air Monitoring Terminal PCB design

Accurate sensor integration is foundational. PCB design must precisely accommodate diverse sensor types (e.g., electrochemical for gases, optical for particulates) with varying electrical interfaces and sensitivities. T - his involves careful placement to minimize cross-interference, dedicated analog-to-digital converter (ADC) interfaces for high-resolution data acquisition, and robust power filtering to ensure stable sensor operation. The physical layout must prevent thermal gradients that could affect sensor accuracy and allow for efficient airflow for gas-sensing elements.

- Why is signal integrity crucial for Urban Air Monitoring Terminal PCBs

Signal integrity is critical because air monitoring sensors often produce low-level analog signals that are highly susceptible to noise. - The PCB design must employ best practices such as impedance matching, proper grounding schemes (e.g., star grounding), differential signaling for sensitive lines,

- and shielding to mitigate electromagnetic interference (EMI) from digital components or external sources.

- Poor signal integrity can lead to inaccurate readings, data corruption, and unreliable environmental assessments.

- What are the primary power management considerations for Urban Air Monitoring Terminal PCBs

Air monitoring terminals frequently operate in remote or off-grid locations, making efficient power management paramount. - PCB designs must prioritize low-power components, optimize power distribution networks to minimize losses, and often integrate sophisticated battery management systems with energy harvesting capabilities

- (e.g., solar panel interfaces). This ensures extended operational lifespan, reduces maintenance costs, and enables continuous data collection without frequent interventions.

- How do environmental factors influence the PCB design for air monitoring terminals

Urban air monitoring terminals are exposed to a wide range of environmental stresses, including extreme temperatures, high humidity, corrosive pollutants, and UV radiation. - The PCB design must account for these by specifying robust materials (e.g., high Tg FR-4, conformal coatings),

- ensuring proper sealing and enclosure interfaces, and designing for thermal dissipation to prevent component overheating.

- Consideration for vibration resistance and ingress protection (IP ratings) is also vital for long-term reliability in outdoor deployments.

- What testing and validation steps are essential for Urban Air Monitoring Terminal PCBs

Rigorous testing and validation are indispensable. This includes functional testing to verify all sensor interfaces and communication protocols, - environmental stress testing (e.g., thermal cycling, humidity chambers) to simulate real-world conditions, electromagnetic compatibility (EMC/EMI) testing to ensure compliance and minimize interference,

- and long-term stability testing to assess drift and reliability over time. These steps validate the PCB's performance and durability before deployment.

Material Selection: Choosing the Right Substrates for Environmental Durability in Urban Air Monitoring Terminal PCB Solutions

PCB Substrate Materials

The operational longevity and data integrity of urban air monitoring terminals heavily depend on the resilience of their Printed Circuit Boards (PCBs) to diverse and often harsh environmental conditions.

The selection of appropriate substrate materials is paramount, as these PCBs must withstand extreme temperature fluctuations, high humidity,

corrosive atmospheric gases, and potential mechanical stresses without compromising performance. A meticulously chosen substrate ensures the reliability and accuracy of sensor readings over extended periods,

making it a critical factor in the overall success of an urban air quality monitoring initiative. This strategic material choice directly impacts the system's robustness,

reducing maintenance overhead and ensuring continuous, accurate data collection vital for public health and environmental policy.

- FR-4 (Flame Retardant 4)

A widely used and cost-effective fiberglass-reinforced epoxy laminate. FR-4 offers good electrical insulation, mechanical strength, and thermal stability. - While suitable for many general-purpose applications, its moisture absorption can be a concern in very high humidity environments,

- potentially leading to dielectric property degradation over time. However, advancements in FR-4 formulations have improved its resistance to environmental factors,

- making it a viable option for indoor or less extreme outdoor monitoring units with proper encapsulation.

- PTFE (Polytetrafluoroethylene)

Also known as Teflon, PTFE is a fluoropolymer with exceptional dielectric properties, extremely low moisture absorption, and excellent resistance to high temperatures and corrosive chemicals. - These characteristics make PTFE substrates ideal for high-frequency circuits and applications exposed to aggressive outdoor elements, ensuring stable signal integrity and long-term reliability

- in challenging environments. Its higher cost, however, generally restricts its use to specialized or high-performance air monitoring terminals where environmental resilience is non-negotiable.

- Ceramic

Ceramic substrates, such as Alumina (Al2O3) or Aluminum Nitride (AlN), offer superior thermal conductivity, excellent dimensional stability, and outstanding resistance to high temperatures, - moisture, and harsh chemicals. Their robust nature makes them highly suitable for high-power applications or sensors operating in extremely harsh conditions

- where thermal management and long-term stability are critical. While ceramic PCBs can be more brittle and complex to manufacture, their unparalleled durability

- ensures exceptional performance in the most demanding urban air monitoring scenarios.

| Material Type | Key Advantage | Environmental Suitability | Cost Implication |

|---|---|---|---|

| FR-4 | Cost-effective, good mechanical strength | Moderate (improved for less extreme conditions) | Low to Moderate |

| PTFE | Excellent dielectric properties, low moisture absorption, chemical resistance | High (ideal for harsh outdoor environments) | High |

| Ceramic | Superior thermal management, chemical resistance, high stability | Very High (extreme temperature/harsh conditions) | Very High |

Manufacturing Processes: Ensuring Precision and Reliability in PCB Fabrication for Urban Air Monitoring Terminals

PCB Manufacturing

The manufacturing process of PCBs for urban air monitoring terminals is a critical determinant of their long-term reliability and accuracy in often challenging outdoor environments.

Precision in fabrication is paramount to ensure that the intricate designs, crucial for sensor integration and stable data acquisition, translate into a robust physical board capable of enduring continuous operation.

Achieving this demands meticulous control over every stage, from material preparation to final testing, thereby guaranteeing the operational integrity and longevity of these essential environmental sensors.

- What advanced etching techniques are employed for air monitoring PCBs

Advanced etching techniques for air monitoring PCBs often involve fine-line etching and differential etching. Fine-line etching enables the creation of very narrow traces and spaces, - essential for high-density interconnects required by sophisticated sensor arrays. Differential etching, conversely, is used to achieve precise control over trace impedance,

- critical for maintaining signal integrity in sensitive analog and high-frequency digital circuits common in environmental monitoring systems.

- These methods ensure optimal signal transmission and minimize interference, leading to more accurate data.

- How does precise drilling contribute to the reliability of air monitoring PCBs

Precise drilling is fundamental for reliable air monitoring PCBs by ensuring accurate alignment of vias and through-holes for component placement and inter-layer connections. - High-precision drilling, often utilizing laser drilling for microvias, minimizes registration errors and stress on the laminate, preventing delamination and ensuring robust electrical connections.

- This accuracy is vital for compact designs and boards exposed to thermal cycling, preventing failures that could compromise continuous operation in outdoor conditions.

- What surface finishes are optimal for air monitoring terminal PCBs

Optimal surface finishes for air monitoring terminal PCBs include Electroless Nickel Immersion Gold (ENIG) and Immersion Silver. ENIG provides excellent solderability, - a flat surface for fine-pitch components, and superior corrosion resistance, crucial for boards exposed to environmental pollutants.

- Immersion Silver offers good solderability and cost-effectiveness while providing a reliable protective layer. These finishes protect the copper traces from oxidation,

- ensuring stable electrical contact points and extending the board's operational lifespan in varied climatic conditions.

- Why is quality control crucial throughout the PCB manufacturing process for these devices

Quality control is crucial throughout the PCB manufacturing process for air monitoring devices to mitigate failures in critical applications. - From incoming material inspection to in-process checks like automated optical inspection (AOI) for trace defects and X-ray inspection for internal layers,

- stringent QC ensures every board meets specifications. Final electrical testing (e.g., flying probe or bed of nails) verifies circuit continuity and insulation resistance.

- This multi-stage validation ensures the PCBs can withstand continuous operation and harsh environments without compromising data accuracy or system reliability.

- What are the common testing procedures for air monitoring PCB solutions

Common testing procedures for air monitoring PCB solutions include In-Circuit Testing (ICT) to check for shorts, opens, and component values; - Functional Testing (FCT) to simulate the operational environment and verify overall system performance; and Environmental Stress Testing (EST),

- such as thermal cycling and humidity testing, to assess durability under extreme conditions. Additionally, signal integrity analysis (SIA) and electromagnetic compatibility (EMC)

- testing ensure the board performs reliably without interference, which is critical for accurate sensor readings and long-term deployment.

Sensor Integration: Optimizing PCB Layout for Accurate Data Acquisition

Sensor Integration

Accurate sensor integration is paramount for reliable urban air monitoring terminals, and the PCB layout critically determines the precision of data acquisition. A meticulously designed

PCB layout minimizes signal interference, ensures stable power delivery, and facilitates optimal sensor performance, directly impacting the integrity and reliability of environmental data collected.

Strategic placement and thoughtful routing are not merely design preferences but fundamental requirements for achieving the high fidelity needed in air quality measurements.

| Sensor Type | Key Integration Considerations | Typical Data Output |

|---|---|---|

| Gas Sensors (e.g., CO, NO2, O3) | Proximity to airflow, shielding from EMI, stable reference voltage, specific analog/digital interfaces | Concentration (ppm, ppb) |

| Particulate Matter (PM) Sensors | Dust ingress protection, clean power supply, optical path optimization, fan control integration | PM2.5, PM10 concentration (μg/m3) |

| Meteorological Sensors (e.g., Temp, Humidity, Pressure) | Environmental sealing, isolation from heat sources, stable voltage, low-noise signal conditioning | Temperature ( °C), Humidity (%), Pressure (hPa) |

| Volatile Organic Compounds (VOC) Sensors | Ventilation optimization, stable heating element control, baseline calibration, rapid response time | VOC concentration (ppb) |

- How does PCB layout affect sensor accuracy in air monitoring

PCB layout profoundly impacts sensor accuracy by influencing signal integrity, power noise, and thermal management. - Poor routing can introduce crosstalk and electromagnetic interference (EMI), corrupting sensor signals. Inadequate power planes can lead to voltage fluctuations that destabilize sensor operation. Additionally,

- improper component placement can create localized heat, affecting temperature-sensitive sensors. An optimized layout ensures clean signals, s

- table power, and appropriate thermal dissipation, which are all critical for precise data acquisition from air quality sensors.

Power Management: Designing Energy-Efficient PCBs for Remote Monitoring Applications

Low Power PCB

For urban air monitoring terminals deployed in remote or off-grid locations, efficient power management is not merely a feature but a fundamental requirement for sustained and reliable operation.

The PCB design must transcend basic functionality, embedding strategies that minimize energy consumption, optimize power delivery, and enable autonomous,

long-term deployment without frequent maintenance or external power dependencies. This proactive approach to power design ensures

the continuous collection of critical environmental data, directly impacting the efficacy and economic viability of air quality initiatives.

- What are the primary power challenges for remote air monitoring terminals

Remote air monitoring terminals face challenges such as limited access to grid power, the need for continuous operation over extended periods, - and variable environmental conditions impacting power generation (e.g., solar availability). This necessitates highly efficient power conversion, robust energy storage,

- and intelligent power consumption management to maximize uptime and minimize manual intervention.

- How do low-power components contribute to energy-efficient PCB design

Utilizing low-power components is a foundational strategy. This includes selecting microcontrollers, sensors, - and communication modules specifically designed for minimal current draw during both active operation and sleep modes.

- The PCB layout must also facilitate efficient power delivery to these components, reducing resistive losses and ensuring stable voltage levels, which is critical for overall system efficiency.

- What is an optimized power distribution network (PDN) on a PCB

An optimized power distribution network (PDN) on a PCB ensures stable, clean power delivery to all components with minimal voltage drop and noise. - This involves careful trace routing, appropriate trace widths, strategic placement of decoupling capacitors, and the use of power planes to reduce impedance.

- A well-designed PDN minimizes power loss, enhances signal integrity, and prevents erratic component behavior, especially in low-power systems.

- Can energy harvesting techniques be integrated into air monitoring PCBs

Absolutely. Energy harvesting techniques, such as solar power integration, kinetic energy conversion, or thermoelectric generators, are increasingly vital for remote air monitoring. - PCBs can be designed with dedicated circuits for maximum power point tracking (MPPT) for solar panels, efficient battery charging controllers,

- and interfaces for other energy sources, ensuring a sustainable power supply even in dynamic environmental conditions.

- What role does battery management play in the sustainability of remote monitoring

Battery management is crucial for the longevity and reliability of remote air monitoring terminals. It involves sophisticated charging and discharging algorithms, - overcharge/discharge protection, temperature monitoring, and accurate state-of-charge (SoC) estimation. An intelligent battery management system (BMS) integrated into the

- PCB ensures the optimal performance and lifespan of the battery pack, extending operational periods between recharges or replacements and making the system more autonomous.

- How does Hycxpcba ensure robust power management in its PCB designs

Hycxpcba leverages its deep expertise in rapid prototyping and specialized PCB design to address complex power management requirements. - We employ simulation tools for power integrity analysis, integrate advanced power management ICs (PMICs), and rigorously test our designs for energy efficiency under various load conditions.

- Our commitment to sustainable design principles ensures that our PCBs for urban air monitoring terminals are not only high-performing but also remarkably energy-efficient and reliable for long-term remote deployments.

Hycxpcba's Expertise in Urban Air Monitoring PCB Solutions

Hycxpcba stands at the forefront of providing bespoke PCB solutions for urban air monitoring terminals, empowering cities and industries to accurately track and manage environmental quality.

Our unparalleled expertise in rapid prototyping, combined with a holistic approach to design, manufacturing, and assembly, ensures that our clients receive not just a PCB,

but a critical component vital for the precision and longevity of their air quality monitoring systems.

- Rapid Prototyping for Agile Development

We accelerate product development cycles by offering industry-leading rapid prototyping services. This enables quick iteration and validation of - designs, significantly reducing time-to-market for urban air monitoring devices. Our agility supports real-time innovation in a fast-evolving environmental tech landscape.

- Comprehensive PCB Design Capabilities

Our seasoned engineers specialize in designing PCBs optimized for the unique demands of air monitoring, including robust sensor integration, exceptional signal integrity, - efficient power management for remote deployment, and resilience against harsh environmental conditions. We translate complex functional requirements into highly reliable and performant PCB layouts.

- Precision Manufacturing and Assembly

Leveraging advanced manufacturing processes and state-of-the-art facilities, Hycxpcba delivers PCBs with exceptional precision and consistency. - Our assembly services ensure meticulous component placement and soldering, guaranteeing the highest quality and reliability for critical environmental monitoring applications. Adherence to strict quality control protocols throughout the entire process is paramount.

| Aspect of Expertise | Hycxpcba's Approach | Benefit to Urban Air Monitoring |

|---|---|---|

| Design for Durability | Selection of advanced substrates (e.g., high-Tg FR-4, specialized ceramics) and conformal coatings. | Ensures long-term operational stability in diverse urban climates, from extreme temperatures to high humidity and pollutants. |

Our commitment extends beyond just manufacturing; we partner with our clients to navigate the complexities of environmental sensor integration and data acquisition, providing solutions that are not only technologically advanced but also economically viable. Our strategic location in Shenzhen, the heart of electronic manufacturing, coupled with our Dubai branch, grants us a unique vantage point in the global supply chain, ensuring efficient resource access and swift delivery.

Case Studies: Real-World Applications of Advanced Air Monitoring PCBs

Air Quality Monitoring Terminal

Real-world applications of advanced urban air monitoring PCBs demonstrate the tangible benefits of high-quality, purpose-built electronic

foundations in delivering accurate and reliable environmental data. These case studies illuminate how specialized PCB designs effectively overcome critical challenges,

enabling robust performance even in demanding outdoor conditions. Investing in superior PCB solutions directly translates to enhanced data integrity,

extended operational lifespans, and ultimately, more effective urban air quality management strategies.

- Case Study 1: Remote Urban Park Air Quality Station

Challenge: Deploying a long-term air monitoring station in a remote urban park with limited power access and exposure to significant temperature fluctuations and humidity.Solution - : Hycxpcba designed a multi-layered PCB incorporating low-power ARM-based microcontrollers, advanced power management ICs for solar and battery integration,

- and high-impedance input circuitry to minimize signal degradation from environmental sensors. An IP67-rated conformal coating was applied post-assembly.Outcome:

- The station achieved over 99.5% uptime for 18 months, providing continuous, accurate data on PM2.5, O3, and NOx levels, with power consumption optimized to extend battery life during prolonged cloudy periods.

- Case Study 2: Industrial Zone Emission Monitoring Array

Challenge: Monitoring various volatile organic compounds (VOCs) and hazardous gases near industrial facilities, requiring high sensor density, - rapid data processing, and electromagnetic interference (EMI) suppression.Solution: A custom PCB with a high-density interconnect (HDI)

- design was developed, featuring dedicated analog and digital ground planes, strategic component placement for thermal management,

- and shielded trace routing for sensitive sensor signals. High-speed data buses were optimized for minimal latency.Outcome:

- The array successfully differentiated between multiple gas sources with high precision, maintaining data integrity despite significant industrial noise,

- and enabled real-time alerts for emission anomalies, leading to improved regulatory compliance.

- Case Study 3: Smart City Integrated Sensor Network

Challenge: Integrating diverse environmental sensors (air quality, noise, temperature, humidity) into existing street furniture infrastructure, requiring compact - PCB designs with robust wireless communication capabilities and long-term stability.Solution: Hycxpcba provided compact, flexible PCBs (flex-rigid boards)

- that could conform to tight spaces within existing streetlights and bus shelters. Integrated cellular IoT modules and advanced antenna designs were incorporated,

- alongside components selected for their extended temperature range and reliability.Outcome: The deployed network provided seamless,

- real-time environmental data across several city blocks, enabling dynamic traffic management based on pollution hotspots and informin

- urban planning decisions, all while blending discreetly into the urban landscape.

The evolution of Printed Circuit Board (PCB) technology is set to profoundly transform urban air monitoring, driving advancements that enable more ubiquitous, accurate,

and energy-efficient environmental surveillance. These innovations are not just incremental improvements; they represent fundamental shifts in how monitoring

terminals are designed, manufactured, and deployed, pushing the boundaries of data collection and real-time analysis for a cleaner urban environment.

- Flexible PCBs: Enabling Wearable and Conformal Monitoring Devices

Flexible PCBs (FPCBs) are revolutionizing air monitoring by allowing devices to be integrated into unconventional forms, such as wearable sensors, - street furniture, or even clothing. Their ability to bend and conform to irregular surfaces opens new avenues for deploying discrete, widespread monitoring

- networks that can collect hyper-local air quality data, providing unprecedented spatial resolution for urban pollution mapping.

- This flexibility also enhances durability by making devices less susceptible to mechanical stress, crucial for long-term outdoor deployments.

- 3D-Printed PCBs: Accelerating Prototyping and Customization for Niche Applications

3D-printed PCBs offer rapid prototyping capabilities and unparalleled design freedom, allowing for highly customized and complex geometries that - are difficult or impossible with traditional manufacturing. This technology drastically reduces development cycles for specialized air monitoring terminals,

- enabling quick iteration and deployment of bespoke solutions for specific environmental challenges or unique urban infrastructures. Furthermore,

- it facilitates the integration of components directly into the substrate, reducing overall size and weight.

- Smart PCBs with Integrated Sensors and Communication: Towards Autonomous Monitoring Nodes

The integration of sensors, microcontrollers, and communication modules directly onto the PCB, creating 'smart PCBs,' is a pivotal trend. - These highly integrated boards enable autonomous monitoring nodes that can sense, process, and transmit data without external components,

- leading to smaller, more robust, and cost-effective terminals. This level of integration supports advanced functionalities such as edge computing for

- real-time data analysis, self-calibration, and robust mesh networking, significantly enhancing the responsiveness and reliability of urban air quality management systems.

- Miniaturization and High-Density Interconnect (HDI) PCBs: Shrinking Footprints for Discreet Deployment

The continuous drive for miniaturization through HDI PCB technology allows for more compact and less intrusive air monitoring terminals. - By enabling higher component density and finer traces, HDI PCBs facilitate the integration of more sophisticated sensor arrays and processing power into smaller form factors.

- This is crucial for discreet urban deployments where aesthetics and minimal visual impact are important, allowing for broader distribution of sensors without compromising the urban landscape.

- Advanced Power Management on PCB: Extending Battery Life for Remote and Sustainable Monitoring

Innovations in PCB-level power management, including advanced DC-DC converters, energy harvesting circuits, and intelligent power distribution networks, - are extending the operational life of battery-powered air monitoring terminals. These advancements are critical for deploying sensors in remote locations without access to grid power,

- enabling long-term, sustainable data collection from a wider array of urban environments and reducing maintenance costs associated with battery replacement.

Conclusion: Partnering with Hycxpcba for a Cleaner, Healthier Urban Environment

In the critical endeavor of urban air quality management, the reliability and precision of monitoring terminals are paramount. At the heart of these indispensable devices

lies the Printed Circuit Board (PCB), acting as the central nervous system that orchestrates sensor data acquisition, processing, and communication. High-quality

PCB solutions are not merely components; they are foundational to ensuring accurate, continuous, and actionable insights into the air we breathe,

directly impacting public health and environmental policy. Hycxpcba stands at the forefront of this vital sector, offering unparalleled expertise and a steadfast

commitment to advancing urban air monitoring capabilities through superior PCB technology.

- Why is high-quality PCB crucial for urban air monitoring terminals

High-quality PCBs are crucial because they ensure the stability, accuracy, and longevity of urban air monitoring terminals. They provide robust signal integrity for sensitive sensors, - efficient power management for continuous operation in various environments, and resilience against harsh environmental conditions. Without a high-quality PCB,

- the reliability of collected data is compromised, leading to inaccurate assessments of air quality and ineffective environmental interventions. This directly impacts public health and the effectiveness of urban planning.

| Key Benefit | Description | Impact on Urban Air Monitoring |

|---|---|---|

| Rapid Prototyping | Accelerated development cycles for custom PCB designs, enabling faster iteration and validation. | Significantly reduces time-to-market for new air monitoring technologies, allowing for quicke r deployment of advanced solutions to address evolving environmental challenges and regulatory demands. This agility is crucial in dynamic urban environments where air quality can change rapidly. |

Hycxpcba, with its deep-rooted experience in rapid-response R&D prototype manufacturing, offers a comprehensive suite of services from initial PCB design to manufacturing and assembly.

Our strategic location in Shenzhen, coupled with a global supply chain network, ensures access to the best resources and a seamless production flow. We don't just produce

PCBs; we engineer the foundation for a healthier future, providing solutions that are meticulously designed for environmental durability, optimal sensor integration, and energy efficiency.

Our commitment extends beyond fabrication, focusing on collaborative partnerships to bring innovative air monitoring solutions to life. We invite you to connect with Hycxpcba to discuss your specific

urban air monitoring PCB needs and together, build a cleaner, healthier urban environment for all.

In conclusion, the effectiveness of urban air monitoring terminals hinges significantly on the quality and design of their PCBs. Hycxpcba, with its expertise in rapid prototyping, comprehensive

PCB solutions, and strategic global presence, is uniquely positioned to empower clients in the environmental monitoring sector. By choosing Hycxpcba, you are not just selecting a PCB provider;

you are partnering with a team dedicated to innovation, quality, and a cleaner, healthier urban environment. Contact us today to explore how our PCB solutions can elevate your air monitoring capabilities.

Together, we can make a significant impact on urban air quality monitoring and contribute to a more sustainable future. Share this article to promote awareness of the importance of advanced PCB solutions in environmental monitoring!